Rift Grain For Table Legs

To have the most consistent and pleasing appearance, a square table leg has similarly straight grain on all four faces. This is achieved by having the annual growth rings running diagonally across the ends of the legs. Where the growth rings meet the four surfaces, the grain will run linearly from the top to the bottom of the leg. The technical term for this orientation is rift grain or rift sawn boards.

A few species are sometimes sawn to produce quartersawn/riftsawn lumber. Examples are cherry, red and white oak, and walnut. But even then, its not easy to find ideal riftsawn lumber for table legs. In an order of lumber for a project, its possible all the thick boards are true quartersawn and none riftsawn.

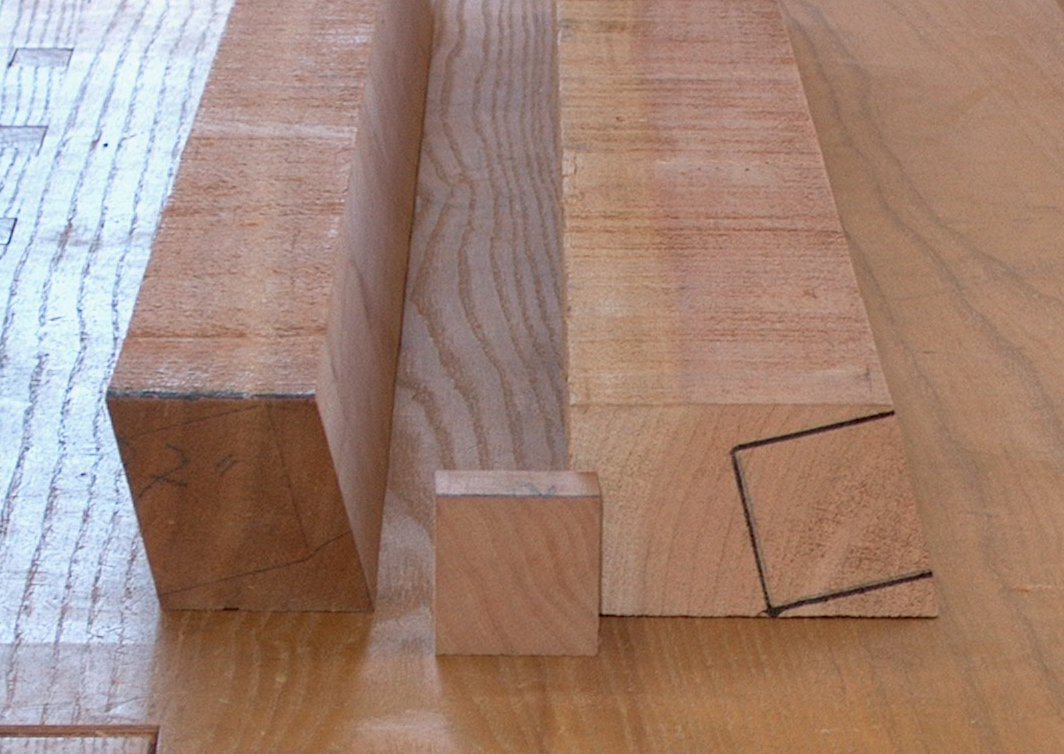

These pieces were cut from 2 thick quartersawn boards. By ripping the boards at an angle, it was possible to obtain riftsawn table legs 1 ¾ square. The center piece is the desired final profile. The piece on the right has been ripped once, the piece on the left twice.

This picture shows two legs that were cut from true rift grain boards, and the above two pieces after one face has been cut perpendicular to the new edges. The orientation of the growth rings is drawn on the ends.

For larger tables, sufficiently thick boards may not be available. Design considerations on a large boat top dining table called for legs 2 ¼ square. The thickest available boards were only 2, so two would have to be glued together. A glue joint running along the face of a leg is not attractive it should run diagonally to be almost invisible.

A pair of boards with quartersawn grain were oriented so that a leg cut as marked would have straight grain on all four faces, and the glue joint running diagonally across the leg.

Return to Best Traditional Woodworking Practices page

Appointments are suggested for your convenience.