Common Board Grain Patterns

Boards are rectangular slabs sawn from logs. To establish some terminology, consider a board that is 60 long, 7 wide, and 2 thick. This board has three pairs of surfaces. The ends are 7 by 2. The edges are 60 by 2. And the faces are 60 by 7.

Looking at the end of this walnut disk, one can see coincentric, alternating light and dark circles, the trees growth rings. The light and dark rings are alternating annual bands of earlywood and latewood. In some species, such as basswood (also known as linden) there is little contrast between the earlywood and latewood rings. In many trees, however, the earlywood is a lighter color than the latewood.

The contrast between earlywood and latewood produces various patterns in the surface of a board, depending on the orientation of the growth rings. The path of the saw blade through the log determines these patterns.

The arches and cathedrals, or ovals and ellipses in this collection of boards result from flat sawing a log.

The grain in these rift sawn boards is very straight without arches and cathedrals.

This diagram shows an end view of four boards in a hypothetical log.

In the top board, the growth rings are more or less parallel or tangent to the two faces. This orientation would make the board flatsawn.

The edges of this board will show rather straight grain lines. The outer parts of the faces will also show rather straight grain lines, but the middle of the faces will be wide bands of grain, often known as arches and cathedrals.

In the second board, the growth rings are diagonal to both the faces and the edges. This orientation makes the board riftsawn.

Both the faces and the edges of this second board will show rather straight grain lines, a much more consistent look than with flatsawn boards. This consistency makes riftsawn boards ideal for rectangular cross-section table legs because all four leg faces will have straight grain lines.

In the third board , the growth rings are more or less parallel or radial to the two edges, making the board quartersawn. The two faces will show very straight grain lines, but the edges will show flatsawn grain patterns.

The fourth board has a mix of flat, rift, and quarter grain.

Except for boards passing directly through the center of the log, most will contain a mix of flat, rift, and quarter grain, as shown by the bottom board.

The above diagram was illustrative of growth ring orientation in a board. However, it does not represent the typical sawing pattern. Logs usually are sawn from one side until defects are uncovered near the center. The log is then rotated 90 degrees and sawing continued, until the defects are reached again. The process continues as shown.

It is important to note that NO quartersawn or riftsawn boards are produced. It is also important to note that all of the boards are basically flatsawn, showing arch and cathedral grain patterns, occasionally with a small amount of riftsawn and less frequently some quartersawn grain pattern at the edges. Finally, on half of the boards the arch and cathedral grain patterns are not centered on the faces of the boards.

The grain orientation should be considered for two reasons.

Growth ring orientation strongly impacts overall appearance of sawn lumber. Very wide arches and cathedrals will dominate the rest of a board. Not everyone likes the look of prominent arches and cathedrals. More moderate arches and cathedrals can add visual interest to furniture. But a mix of centered and offset arches and cathedrals looks bad. And some people will find a piece made entirely with quartersawn lumberlacks drama and contrast.

The second reason to consider grain orientation is that wood is dynamic. Even after thorough drying, wood will expand and contract with changes in humidity. But wood does not expand and contract equally in all directions.

Along its length, the change is so slight as to be inconsequential in most cases.

Along its width, or tangentially in this diagram, the net change, on average, is generally considered to be one-eighth to three-sixteenths inch per foot. Minor changes in thickness are usually not a concern in furniture, but three-sixteenths inch per foot of width can cause significant splitting and cracking, and break joints, if such movement is not anticipated.

Along its thickness, or radially, the net change, on average is about half of the tangential rate.

A flatsawn board, because tangential shrinkage is greater than radial shrinkage, will cup towards the bark side as it dries. When the board reaches a stable moisture level, movement stops. But should humidity change, the board will cup further or flatten slightly as the humidity level decreases or increases. Thus it is important to store new lumber in the workshop for a week or two before beginning to work it. This time allows the lumber to adjust to the humidity level there.

This ash tabletop consists of five flatsawn boards. The arches and cathedrals were not centered on all of the boards, so about an hour was needed to carefully trim the edges to create a more balanced look. The piece is in the style of French vineyard provincial tilt-top tables, so the more informal grain pattern is appropriate.

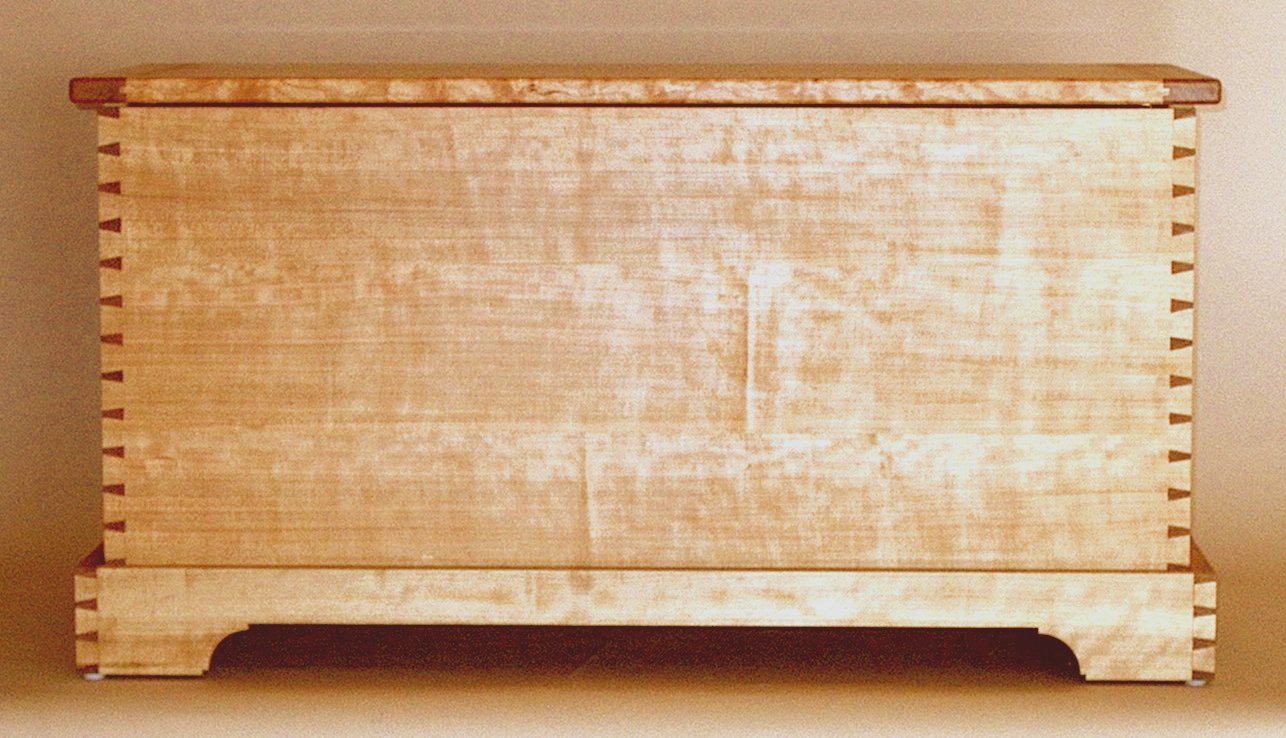

The quartersawn boards on the front of this blanket chest create a much more formal look.

Return to Best Traditional Woodworking Practices page

Appointments are suggested for your convenience.